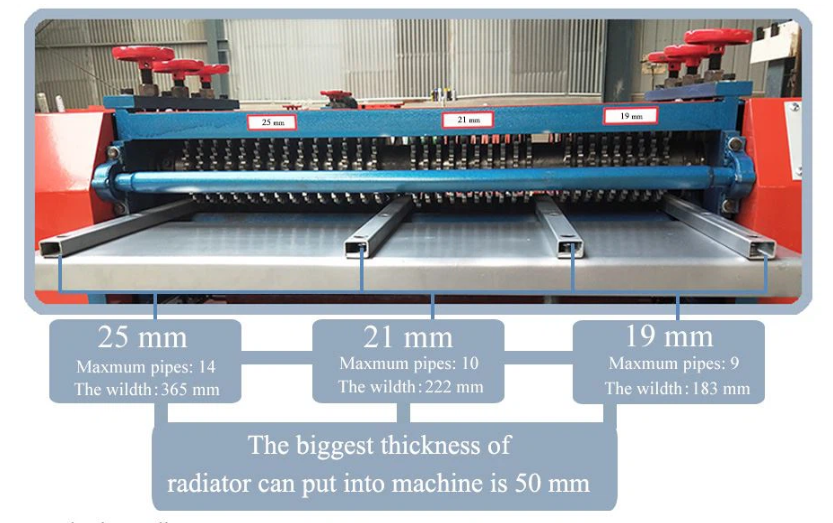

Yuteng Machinery Factory supplies radiator copper and aluminum separator YK-853:1: 2 copper tube center distance level is 19mm, 21mm and 25mm2: More powerful and heavy-duty structure3: Support customi

1.Machine Introduction

YK-853 Radiator Copper and Aluminum Separator is designed by Yuteng Machinery and has an invention patent. The machine is environmentally friendly and has no pollution to the environment.

YK-853 consists of a frame, 2 motors and 2 reduction boxes, waste radiator feed plate, cutting parts, transmission parts and material separation parts. This radiator stripping machine is suitable for flat and non-bent waste radiators in air conditioners, car/auto radiators or water tank radiators.

2.Machine Main Parts

1) Motor: 2 motors, we use Shanghai Minglu motor, it is a famous brand motor in China.

2) Reducer: Use Huiyi brand reducer, excellent quality.

3) Electrical control components: Delixi big brand, stable performance.

4) Blade: Use forged steel blade, the machine has 69 blades including 29 small blades and 40 large blades.

Notes:

One machine can process three different copper tube center distances at most;

Usually, most of the scrap radiators in the market are 19mm,21mm, and 25mm.

If your scrap radiator has other distances, pls let us know. We will customize the machine for you.

This machine proved to be the best choice for recycling used radiators.

3.Machine Advantages

1) This machine is easy to operate, and the occupied area is small.

2)This machine improves copper recycling efficiency essentially and saves labor.

3)The copper tube will keep complete after being stripped and thus reduce the copper loss to the minimum.

4) After stripping, the copper tube and the aluminum can be separated completely and there is no secondary pollution.

5) BS-1200P can strip and separate all kinds of radiators, such as air conditioner radiators, car radiators, etc, for recycling copper and aluminum.

4.Machine Structure

Scrap AC radiator separating machine to cut aluminum foil and separate copper tube one time;

first through the first row of the roller to pulling the raw material into machine;

after via second blades roller to cut the aluminum foil;

third, the cut aluminum foil and the copper tube will work via third roller pressing, thus can reach fully separating one time.

Notes

1) The radiator iron head must be cut off from both sides of the radiator;

2) The radiator must be cut with a band saw according to the width of each feed port; Radiators with more than 2 layers must be cut into one or two layers with a band saw;

3) Do not feed the radiator into the wrong feed port the three feed ports correspond to 19mm, 21mm, and 25mm radiators respectively.

4) When processing a double-layer radiator, the left side of the radiator must be in contact with the left side of each feed port, and the first copper tube on the upper layer on the left side of each feed port must be closer than the first copper tube on the lower layer on the left side of each feed port.

5) Regardless of single-layer or double-layer radiators, the left side of the radiator must be in contact with the guide ruler, and the radiator must be fed into the feed port along the guide ruler.

6) When the radiator is correctly fed into the feed port, each feeding gear at the feed port must be located in the middle of every two copper tubes, otherwise the copper tube and the aluminum tube cannot be separated.

7) Twisted radiators cannot be processed.

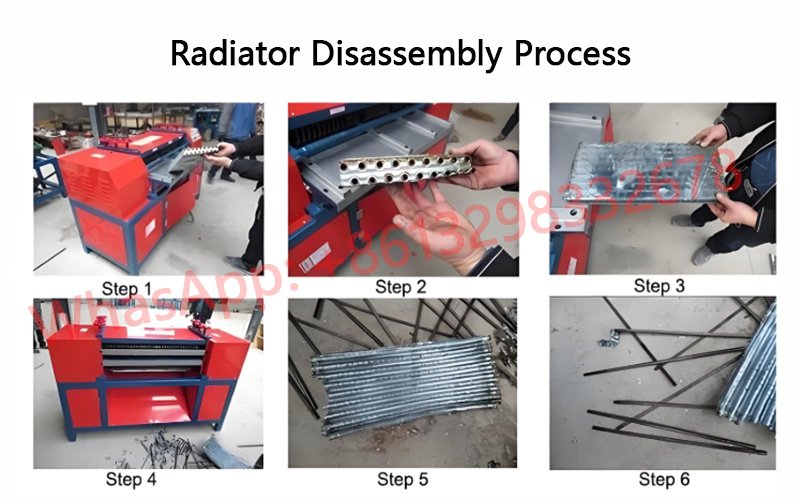

5.Working steps

1)Turn on the reversing switch and check the direction of rotation.

2)Inject lubricating oil into the two oil holes on the left and right sides of the machine to lubricate the transmission gear,generally once every 4 hours of work.

3)Push copper and aluminum radiators of different specifications19mm, 21mm, 25mm, into different feed ports for separation; the left side of the radiator must touch the left side of the feed port, or the right side of the radiator must touch the right side of the feed port,the first copper tube on the lower layer should be close to the guide ruler,when the radiator is pushed into the feed port, the feed gear will bite the radiator and bring it into the machine.

4)After the radiator enters the equipment, the copper tube and aluminum material are automatically separated and automatically come out of the machine.

5)According to the number of layers and height of the radiator, adjust each pair of adjustment wheels on the machine ,tighten the lower screws after adjustment.

6.Applicable materials

7.Copper and aluminum separation effect

8.YK-853 Frequently Asked Questions

1)Can you make a single-phase machine?

YK-853 only can be made three-phase machine, Single-phase can't drive the machine.

2)What is the processing range?

The center distance of 2 copper pipes in the level radiator is 19mm,21mm, and 25mm. If another center distance, we can customize it for you.

When the radiator center distance is 25mm, it can process 14 pieces of copper pipe. the processing radiator big width is 360mm

When the radiator center distance is 21mm, it can process 10 pieces of copper pipe. the processing radiator big width is 220mm

When the radiator center distance is 19mm, it can process 10 pieces of copper pipe. the processing radiator big width is 180mm

3)How long time I need to change blades?

Usually, when processing the scrap radiator output reaches 300T, maybe need to change several blades. This is not absolutely according to blades' situation. And we also have blades changing video for your reference.

4)What's the maintenance for the machine?

All our machine warranty is one year. Besides blades needing to change, machine other parts don't need to change, and quality is good.

5)How to change the machine from 1 layer to 2 layers?

When the radiator is 1 layer, you can process it directly.

When the radiator is double-layer, you can adjust the handle

TEL

+86 13298332678

Work time

from Monday to Friday

After sales service

+86 13253662638