Release time:2025-04-17

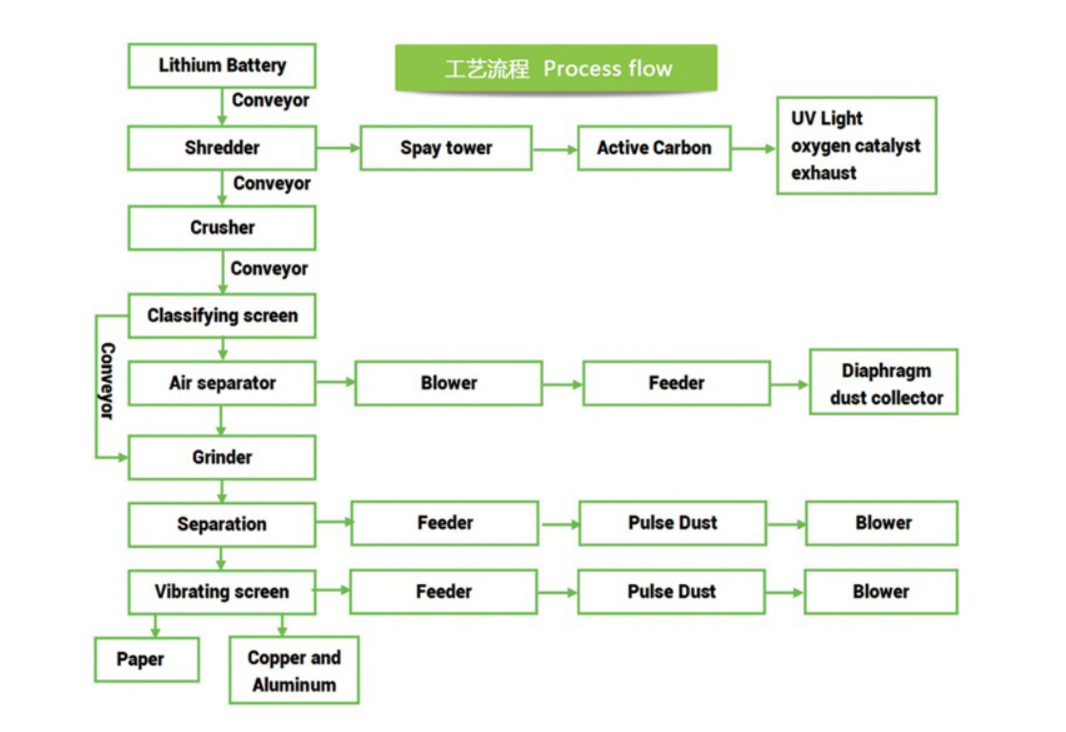

Lithium battery electronic products can be seen everywhere in our daily life. Compared with mobile phones, laptops, tablets, electric toothbrushes, and electric vehicle products, a large number of waste lithium batteries are generated every year. So how can these lithium batteries be recycled to turn waste into treasure? At present, the recycling of waste lithium batteries mainly adopts mechanical and physical methods, which can effectively avoid secondary pollution in the recycling process. The new lithium battery crushing and recycling equipment solves the problem of recycling and processing of waste lithium batteries. The new lithium battery crushing and recycling equipment is a relatively environmentally friendly solution for the recycling and processing of waste lithium batteries. Lithium battery recycling can concentrate on recycling precious metals in positive electrode materials, and separate aluminum and lithium cobalt oxide in the positive electrode materials of waste lithium batteries, and separate diaphragm paper. The system includes a feeding platform, a conveyor, a crusher, an analyzer, an induced draft fan, a collection device, a pulse purifier, and a grading screening machine. The entire production line of lithium battery processing equipment adopts physical treatment methods such as mechanical crushing and separation to recycle and separate the positive electrode materials in lithium batteries. The whole process does not add any chemical components, does not use any chemical external treatment process, and is completely green and environmentally friendly. The process flow is as follows:

1. The material from the conveyor is sent to the primary crusher for coarse crushing, and the coarsely crushed material is sent to the secondary crusher through the conveyor for secondary crushing.

2. The material crushed by the second crusher enters the conveyor, and a magnetic separation device is set to separate the iron in the material

3. After iron removal by the material conveyor and magnetic separator, it enters the third crusher for fine crushing and crushes the material into powder.

4. The powdered material enters the cyclone separator through the negative pressure system for air filtration, and falls to the air separator through the fan. After sorting by the air separator, the materials of different densities are layered, the metal sludge is sorted, and all non-metals are brought into the pulse dust collector by the negative pressure system for concentration.

5. The filtered exhaust gas will continue to be sent to the exhaust gas treatment equipment by the negative pressure system for air purification, so that it can be discharged at high altitude after meeting the emission standards.

The recycling of waste lithium batteries mainly focuses on the recycling of positive electrode materials, negative electrode materials and waste hard shell batteries. During the recycling process, waste lithium batteries will release residual electricity, which is convenient for recycling. The positive electrode materials of waste lithium batteries contain cobalt, nickel, lithium aluminum and other metals.

Through the copper and aluminum re-screening technology of the new waste lithium battery crushing and recycling equipment, the recycling value of waste lithium batteries is doubled, which promotes the improvement of the economic benefits and efficiency of lithium batteries, and becomes the key equipment for the transformation and upgrading of the lithium battery industry and waste lithium battery production lines and sustainable development. The environmental protection treatment technology of waste lithium battery treatment equipment has truly solved the problem of lithium battery recycling and treatment.

The above is a detailed introduction to the recycling and reuse of waste lithium batteries. I believe you also have a certain understanding.

If you are interested in related equipment or projects, please feel free to contact us at any time, we will serve you wholeheartedly!

TEL

+86 13298332678

Work time

from Monday to Friday

After sales service

+86 13253662638