Release time:2025-05-15

Tire crushing and recycling production line workers need to recycle and reuse waste tires from different types of vehicles such as cars, light commercial vehicles, trucks, and engineering machinery, including crushing processing, steel wire and fiber sorting, and producing pure rubber particles and powders.

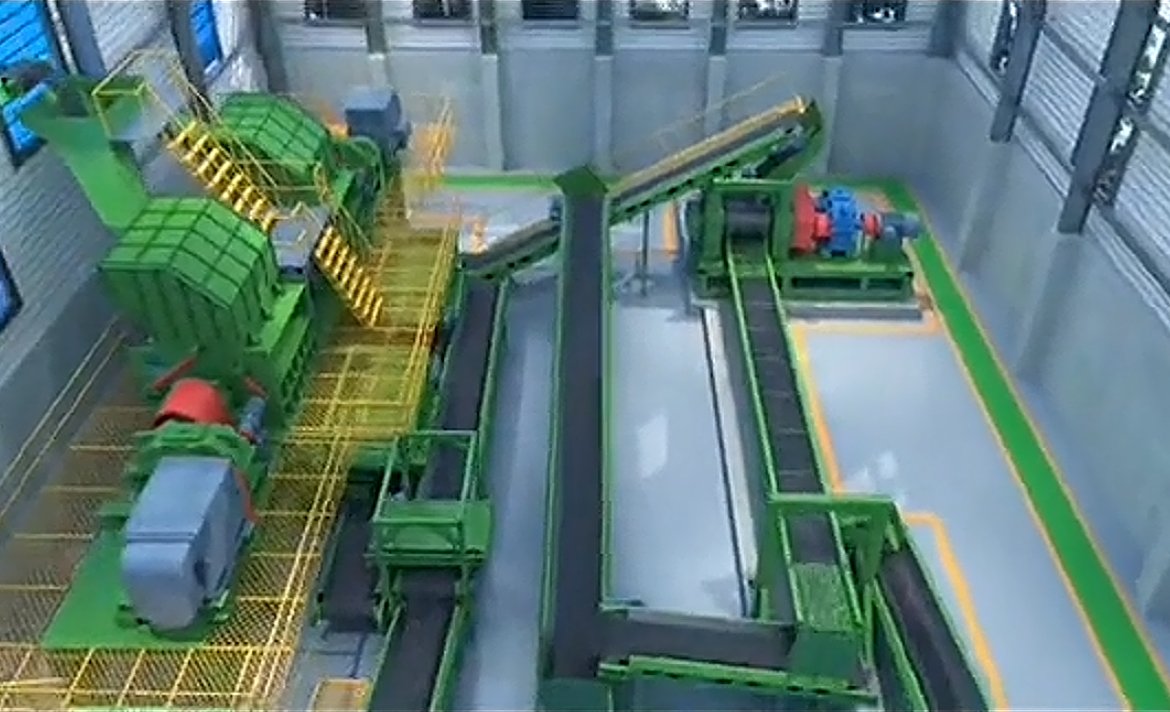

The production line structure may include:

1. Fully automatic wire drawing machine: remove tire and wheel rims

2. Conveyor equipment: conveyor belt, screw conveyor, and pneumatic transmission system

3. Shredder: shred tires into thin films (50mm-150mm)

4. Steel wire separator: Separate rubber and steel wire and process them into rubber particles (10mm-20mm)

5. Magnetic separator: Separate the mixture of steel wire and rubber steel wire

6. Crusher: Grind rubber particles into smaller sizes (1mm-7mm)

7. Vibration screen: Sort rubber particles of different sizes and send the oversized particles back to the crusher for secondary crushing

8. Fiber separator: Remove foreign objects and fibers

9. Secondary magnetic separator: Remove small steel wires that may remain in their original position

10. Crusher: Grind particles into powder (30-100 mesh)

11. Fully automatic bagging system: Features for loading finished products into storage or packaging bags

The entire tire is placed directly without pre pressing or pulling the wheel rim. From the whole tire to the 1-7mm particles, the entire process is produced and packaged without the need for secondary processing intermediate links. The maximum processing capacity is 5000kg/h, and up to 7 people are needed to complete all on-site operations. Equipment models are configured according to customer production requirements, ranging from 200kg/h to 5000kgh, with a wide range of choices. The fully modular two-layer structure makes installation, replacement, maintenance, and upkeep more convenient and safe, seamlessly connected, and fully monitored for dust and smoke throughout the process. We insist on conducting feeding experiments 80-100 hours before leaving the factory to ensure stable performance.

TEL

+86 13298332678

Work time

from Monday to Friday

After sales service

+86 13253662638